Page 1 of 3

General Info: Broken Exhaust manifold Stud

Posted: Sat Jun 14, 2008 4:02 pm

by JG

stud, bummer

Looking at engine, bottom right hand stud, looks and feels at though it's broken flush with the head. Not blowing at present, so will keep an eye on it for time being.

Now, I have a spare 2.3 head with cams and sprockets. (140k) Needs a skim so may just get that checked over and just replace head for head...

Comments please.

Re: Just found a broken Exhaust manifold

Posted: Sat Jun 14, 2008 4:48 pm

by ylee coyote

they all break there...

I have had 3 go there

your manifold gasket will go next and then it sounds like a tractor

DO NOT TRY TIGHTENING THE OTHERS TO COMPENSATE

you will break them

it can be succesfully drilled out in situ

need a steady hand ,cobalt drills and a right angle attachment to get into the space

you also need something to keep it central in the hole

or you could swap the head

hour job v a full day ....

Re: Just found a broken Exhaust manifold

Posted: Sat Jun 14, 2008 4:50 pm

by Robert

Andy,

I had three go in my 9000. I made a jig and drilled them in situ (had to buy a 90º air drill and some cobalt bits and a decent easy out.)

Bit fiddly.

Robert

Re: Just found a broken Exhaust manifold

Posted: Sat Jun 14, 2008 5:24 pm

by ViggenNut

Strange... also had one go on my GM900 about 2 years ago, SAAB dealer drilled it out and extracted it.... funny but I didn't notice it was broken for some time, then one day errrr... where's me bolts gone

Re: Just found a broken Exhaust manifold

Posted: Sat Jun 14, 2008 5:54 pm

by Robert

Andy,

I could post my drill down to you if you want (you'd need an air supply though, my Suzy hose is unlikely to be long enough

) you'd need to supply your own drills and extractor and I can have a look for the jig.

R

Re: Just found a broken Exhaust manifold

Posted: Sat Jun 14, 2008 6:33 pm

by JG

Robert wrote:Andy,

I could post my drill down to you if you want (you'd need an air supply though, my Suzy hose is unlikely to be long enough

) you'd need to supply your own drills and extractor and I can have a look for the jig.

R

Thanks Rob, most decent of you. I have not got a compressor, very limited workshop....Could we WiFi the compressed air down to here, or maybe down the BB line?

I have just looked at the 2.3 head I have, the studs on the exhaust manifold are new, with collars and nuts. Head just needs a clean up, so maybe get it skimmed, or just scrap it clean. I have been keeping this head for some reason, maybe because I could not find a buyer. If I understand right, the 2.3 is a straight swap, and has better porting ?

This may sound strange, but with the tools I have, it maybe easer just to swap heads than start drilling out studs. and if the 2.3 gives a benefit for engine performance and MPG

Funny how thing happen at 100k, the LH HL wiper has stopped working today as well

Thanks anyway Rob, if I can find a compressor then I might just take you up on your offer of the drill and jig. Once I start unscrewing the remaining nuts, I will probably see them go as well.

Time to ponder this over a few glasses of red....

Re: Just found a broken Exhaust manifold

Posted: Sun Jun 15, 2008 1:42 pm

by JG

Re: UPDATED....Just found a broken Exhaust manifold

Posted: Sun Jun 15, 2008 4:07 pm

by Robert

Andy,

You may be able to ficx that without taking the manifold off.

Get someone down there to make you up a short length (or two short lengths) of bar (the harder the steel the better, ) both diameters large enough to be a tightish fit in the manifold stud hole (the hole on the manifold)

Get a hole bored down each one, the first Ø3,1mm , the other Ø5,1mm

Put the one with the smaller hole into the stud hole. Using a 90º drill and a Ø3mm COBALT drill drill out the centre of the broken stud. Low speed, minimum pressure. MAke sure you go all the way through the stud - there is a void between the base of the stud and the bottom of the hole.

Repeat the procedure with the Ø5,1mm drill and larger guide.

The more material you can safely remove from the stud centre the more you will reduce the binding stresses on the threads.

Using a good quality (e.g. Dormer, presto) easy out carefully wind the remnants of the broken stud out. Apply even pressure and no sideways force of the easy-out will snap. They are tremendously hard, but cannot take a side load. It is important that the hole is deep enough for the easy-out to get jammed against the wall of the drilled out stud, rather than bottoming out.

If you can buy a set of 5 easy-outs for £4-99 DON'T. You really need to be paying that sort of money or more, for one.

Re: UPDATED....Just found a broken Exhaust manifold

Posted: Sun Jun 15, 2008 5:00 pm

by JG

Robert wrote:Andy,

You may be able to ficx that without taking the manifold off.

Get someone down there to make you up a short length (or two short lengths) of bar (the harder the steel the better, ) both diameters large enough to be a tightish fit in the manifold stud hole (the hole on the manifold)

Get a hole bored down each one, the first Ø3,1mm , the other Ø5,1mm

Put the one with the smaller hole into the stud hole. Using a 90º drill and a Ø3mm COBALT drill drill out the centre of the broken stud. Low speed, minimum pressure. MAke sure you go all the way through the stud - there is a void between the base of the stud and the bottom of the hole.

Repeat the procedure with the Ø5,1mm drill and larger guide.

The more material you can safely remove from the stud centre the more you will reduce the binding stresses on the threads.

Using a good quality (e.g. Dormer, presto) easy out carefully wind the remnants of the broken stud out. Apply even pressure and no sideways force of the easy-out will snap. They are tremendously hard, but cannot take a side load. It is important that the hole is deep enout for the easy-out to get jammed against the wall of the drilled out stud, rather than bottoming out.

If you can buy a set of 5 easy-outs for £4-99 DON'T. You really need to be paying that sort of money or more, for one.

Gotcha, I would have thought of that, some time

Brill idea. Will get them made up this week. In fact, I'm picking up two colliers I have had made out of Phosphorus Bronze tomorrow, I'll ask the guys to make me up two.

The length only needs to be twice a thick as the manifold. I have an old manifold as a template for the hole diameter.

Thanks Rob.

Re: UPDATED....Just found a broken Exhaust manifold

Posted: Mon Jun 16, 2008 9:37 am

by SPG66

Robert, thanks for the info, I too will get some made up ready as mine has a slight blow.

JG, could you post the diameter required to fit the exh manifold when you have checked, thanks.

This is exactly the sort of usefull knowledge that this forum is so good for.

Re: UPDATED....Just found a broken Exhaust manifold

Posted: Mon Jun 16, 2008 12:11 pm

by JG

I'm have two made as we write, made out of 13mm silver steel. turned down to fit the manifold hole which is 11mm, the length is going to be 26mm, so that's twice the thickness of the manifold. 2 of, one with a 3.1mm hole all the way through, the other 5.1mm. as per Robs post. when made, I'll post photos when I get them home. £20, may seem a tad expensive, but will last, with drill bits & easy out, say another £20, still cheaper than getting a garage to do it.

Andy

Re: UPDATED....Just found a broken Exhaust manifold

Posted: Mon Jun 16, 2008 12:16 pm

by Robert

26mm might be a bit long. Whatthat means is you will have to have a drill bit of length 26mm plus the length of the stud stump, say 15mm. The longerthe drill (especially in relation to its diameter, the more likely it is to snap. OK it is guided along the length but even so...

Re: UPDATED....Just found a broken Exhaust manifold

Posted: Mon Jun 16, 2008 1:05 pm

by Saturbo

Remember to clear the swarf out of the drill as you go? Clogged drill will certainly break.

I actually use left handed drill bits for removing this type of broken screw - the heat and vibration of drilling often lossens the stud and the left hand rotation unscrews it. I believe there is a device available from good toolstores nowadays? JML or something like it?

Re: UPDATED....Just found a broken Exhaust manifold

Posted: Mon Jun 16, 2008 2:06 pm

by JG

Saturbo wrote:Remember to clear the swarf out of the drill as you go? Clogged drill will certainly break.

I actually use left handed drill bits for removing this type of broken screw - the heat and vibration of drilling often lossens the stud and the left hand rotation unscrews it. I believe there is a device available from good toolstores nowadays? JML or something like it?

That's an idea Saturbo, we have a very good tool shop in town, I'll be going there for the bits and EO.

Rob, I did ponder the length, 26mm, I'll be buying the bits and will check on the bit length with jig when I pick them up, so will be able to cut down then. How much stud if let in the head? 10mm I was thinking. +/- 2mm

Re: UPDATED....Just found a broken Exhaust manifold

Posted: Mon Jun 16, 2008 3:19 pm

by Robert

you're not going to believe this but I have a spare Stud in my briefcase. the thread length is 10mm so your estimate will be about right, although the tolerance will be all plus and no minus.

Re: UPDATED....Just found a broken Exhaust manifold

Posted: Mon Jun 16, 2008 3:38 pm

by JG

Robert wrote:you're not going to believe this but I have a spare Stud in my briefcase. the thread length is 10mm so your estimate will be about right, although the tolerance will be all plus and no minus.

Hope your wife does not know about this

So, we have a 10mm stud + 13mm for the thickness of the exhaust manifold + the 26mm for the jig - the 13mm EM + 2mm (app.) of space between the base of the stud and the head.

10+13+26+2 = 54 - 13 = (hang on while I work this out........) 41mm. so as long as there's 43mm from chuck to bit tip, should be fine.

Any questions ?

Re: UPDATED....Just found a broken Exhaust manifold

Posted: Mon Jun 16, 2008 4:02 pm

by Robert

Euler buckling loads Andy.

the thing is it isn't just the length of the drill. It is also a factor of the slenderness ratio. for a long thin rod, there is a limit as to how much load you can put on it before it buckles. A high strength bit will take very unkindly to any form of buckling and will snap. as an extreme case imagine if thedrill wasn't 1m long, it would bend/snap easily. If it were 10mm long it would be very difficult. the closer you get to even presure down the central axis of the drill the better.

You are drilling in poor conditions into a hole you can't see, using a hand held drill horizontally.

the drill needs to be as short as possible, and the only variable is the length of the guide.

for the 5mm drill, you can go longer.

once you have got a decent start, the drill will be guided by the guide and the depth of hole already drilled. you could then consider feeding a little more out of the chuck.

Re: UPDATED....Just found a broken Exhaust manifold

Posted: Mon Jun 16, 2008 4:50 pm

by JG

Robert wrote:Euler buckling loads Andy.

the thing is it isn't just the length of the drill. It is also a factor of the slenderness ratio. for a long thin rod, there is a limit as to how much load you can put on it before it buckles. A high strength bit will take very unkindly to any form of buckling and will snap. as an extreme case imagine if thedrill wasn't 1m long, it would bend/snap easily. If it were 10mm long it would be very difficult. the closer you get to even presure down the central axis of the drill the better.

You are drilling in poor conditions into a hole you can't see, using a hand held drill horizontally.

the drill needs to be as short as possible, and the only variable is the length of the guide.

for the 5mm drill, you can go longer.

once you have got a decent start, the drill will be guided by the guide and the depth of hole already drilled. you could then consider feeding a little more out of the chuck.

10+13+26+2 = 54 - 13 = 41mm. so as long as there's 43mm from chuck to bit tip, should be fine.

Your avg. 5mm bit is about 85mm long, so if there is 43 sitting out of the chuck, that leaves 42mm in the chuck. to start off with there would only need to be 41mm out, which would give 2mm cutting to get started, giving a bit more length as you go. 39mm would be in the jig with 0.5mm air gap. taking 15mm off of the jig will give you 24mm in. would that 15mm make a big difference, maybe, I'll get the jig cut back by 15mm

Re: UPDATED....Just found a broken Exhaust manifold

Posted: Sun Aug 31, 2008 11:45 am

by JG

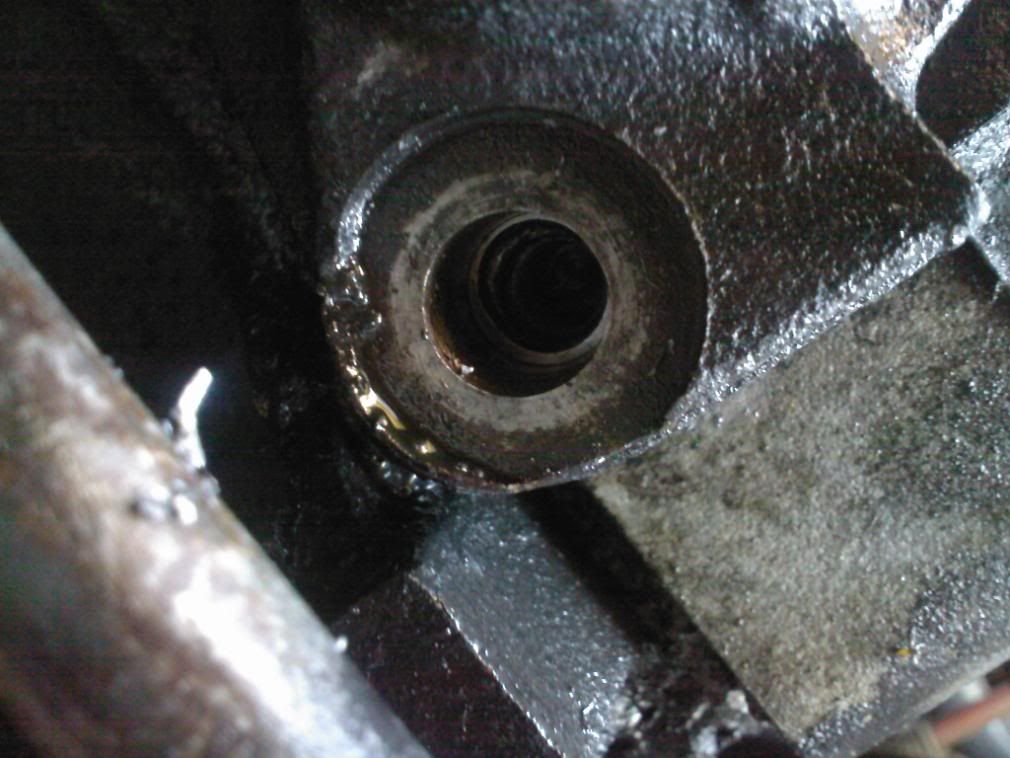

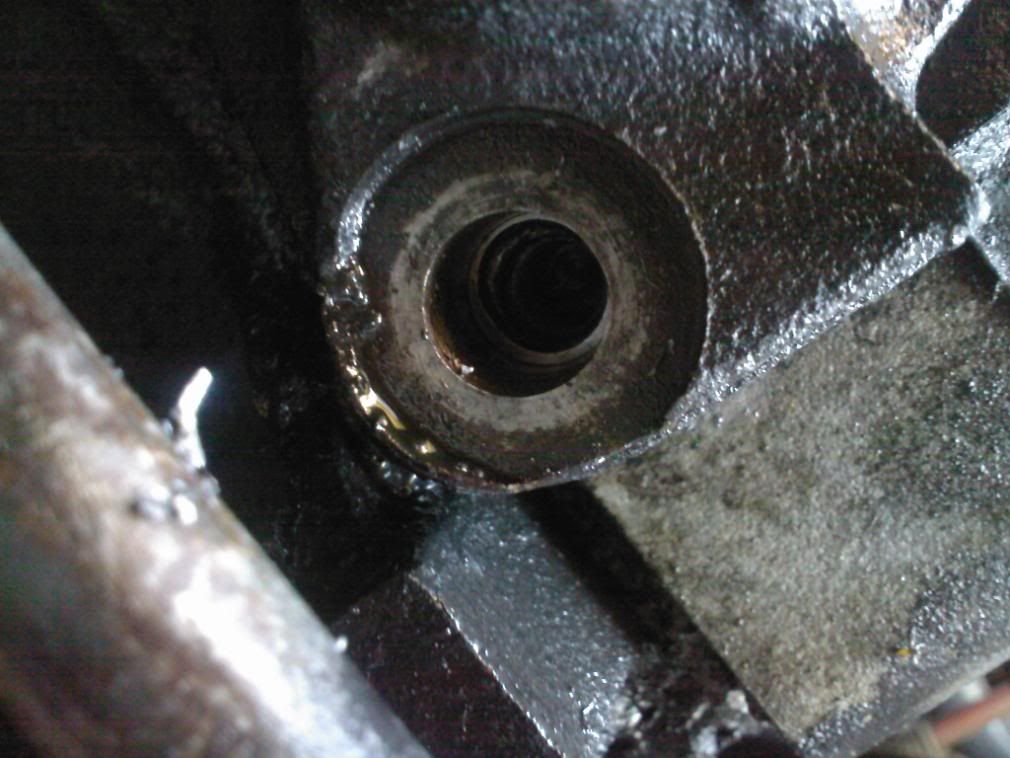

The Tools, The Hole, The Stud.....

Just got around to doing this job. How did it go? Well apart from the 5mm drill chipping it's edge, it went very well.

Thanks to Rob (TB) for his design of tool, jig to do the job, all in, it took 60 of your Earth minutes, 4 cups of black coffee and a bit of sweat.

I removed the Rad fan, turbo inlet tube to give me more room to move.

Now for some Photos.

Re: UPDATED....Just found a broken Exhaust manifold

Posted: Sun Aug 31, 2008 1:12 pm

by ylee coyote

nice job

And I love the guides

the guide I used was a random non identifiable thing picked out the bottom of the toolbox with the right OD for the manifold with a hole up the middle, and I selected the(small) drill size to suit....

once the hole was started it formed the guide for the bigger drill

When can I expect to see the kit down at my local Machine Mart ?

bet lots of people would buy them (well saab guys with b23x motors anyway....)

well done ....